Mucking Loader With Breaking Hammer

Monitoring and inspection

• The inspection of equipment for the tunneling works shall be carried out by the experts (e.g., equipment engineer or equipment foreman) in accordance with the existing specifications of the country where the user is located (e.g., German Accident Prevention Regulation):

• Before the equipment is put into operation for the first time and after the major changes are completed;

• At least once a year;

• At the same time, according to the operating conditions and local environment.

• Keep the inspection report and archive the documents until the next inspection.

• Check the equipment for tunneling work according to the inspection plan before the start of each shift.

• The hydraulic hoses shall be replaced immediately after the following damages are found:

• The outer layer is damaged and the middle layer is affected;

• The outer layer has partial wear;

• The deformation under compression and non-compression is different from that of the newly installed hose;

• It is leaky;

• The hose joint is damaged or the connection between the connector and the hose is damaged.

• The coolant level can be inspected only after the motor is closed. The tank cover shall be rotated to release the excessive pressure.

• Check the functions of the security device before using equipment.

• In case of any failure, the relevant person in charge shall be notified immediately, and the next operator shall be informed during the shift change.

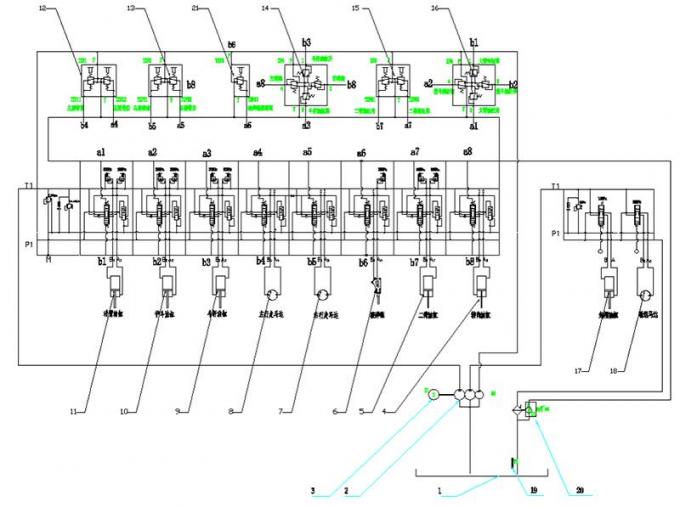

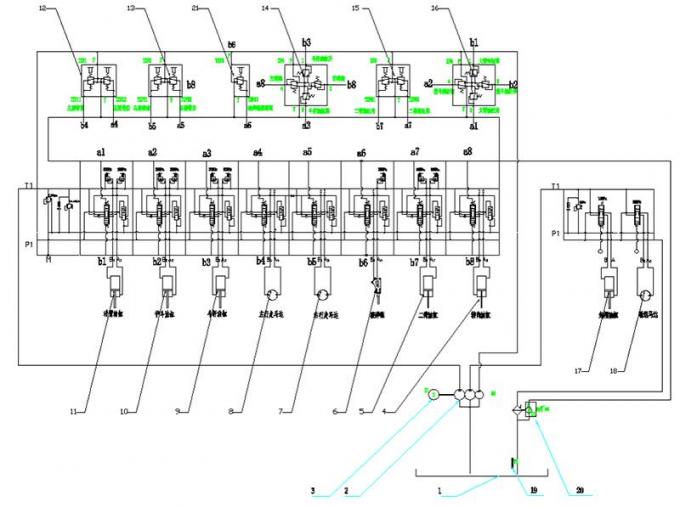

Hydraulic system diagram:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!